Refrigerant Recovery Business

Refrigerant Recovery Business

Refrigerant Recovery Business

Refrigerant Recovery Business

As a refrigerant recovery business registered under the Clean Air Conservation Act, we provide safe and environmentally friendly refrigerant recovery services using specialized equipment and technical personnel.

| Refrigerant Management System

According to the Refrigerant Management System of Chapter 5, Paragraph 2 of the Clean Air Conservation Act (effective November 29, 2018), refrigerant recovery and injection must be done directly by users with self-certified equipment and facilities or by entrusting the process to a registered refrigerant recovery business operator.

| Subject to Regulation

| Status of Professional Equipment Possession

Refrigerant recovery machine

High-efficiency refrigerant recovery safely recovers various refrigerant types (R-22, R-410A, R-134a, etc.). The automatic recovery system ensures fast and accurate operation.

Digital manifold gauge

Monitor refrigerant status in real time with a digital manifold gauge capable of precise pressure measurement, maximizing work efficiency and accuracy.

Vacuum pump

The inside of the system is completely vacuumed using a high vacuum pump.

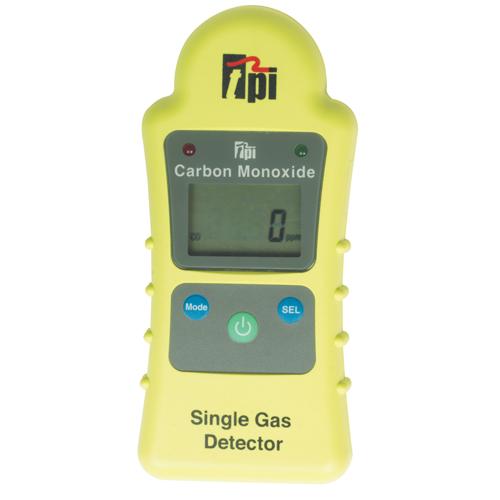

Leak detector

Electronic leak detectors accurately detect even the smallest leaks, ensuring perfect operation.

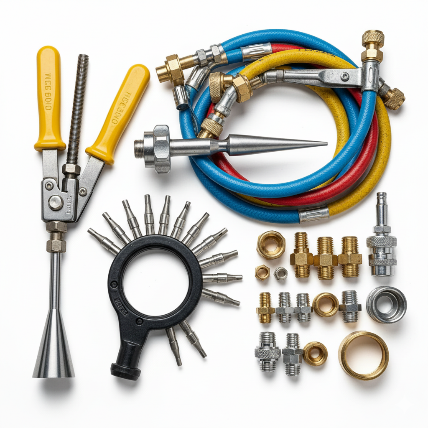

Professional tool set

We have a wide range of specialized tools, including flaring tools, copper pipe expanders, refrigeration hoses, and adapters, to accommodate all types of refrigerant systems.

| Refrigerant Recovery Process

1. Consultation with business partners

Identifying customer requirements and conducting preliminary on-site surveys

2. Review the status of facilities

Detailed review of refrigerant type, capacity, and facility status

3. Calculating the quotation

Accurate cost calculation based on scope of work

4. Contract Conclusion

Confirm work schedule and conditions

5. Refrigerant recovery complete

After performing specialized work, create and deliver a management ledger

| Essential Requirements for a Refrigerant Recovery Specialist

| Refrigerant Recovery Site Case