Refrigeration & Air Conditioning Engineering Industry

Cold Storage Design

Refrigeration & Air Conditioning Engineering Industry

Cold Storage Design

| Overview of the Refrigerated and Freezer Logistics Center

01

The refrigerated logistics center is a storage facility within the cold chain supply chain process, requiring specialized refrigeration technology.

02

We have specialized technology and personnel in refrigeration and freezing, and we perform engineering to implement environmental control functions in refrigerated logistics centers.

03

The main items managed by the refrigerated and frozen logistics center are wide-ranging, including agricultural, fishery, and livestock products, dairy products, fresh food, flowers, pharmaceuticals, and chemical products.

04

As economic development continues, social demand for fresh food supplies is growing, and refrigerated logistics centers are a key component of the cold chain system that provides the solution.

| Refrigeration Engineering Step-by-Step Implementation Contents

- Research technical information on applicable systems, equipment, and auxiliary devices

- Gather ideas and data based on the project theme

- Layout and space planning.

- Energy efficiency planning.

- Hazard prediction and minimization measures.

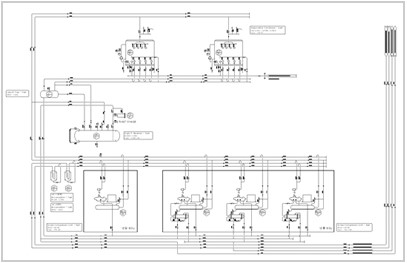

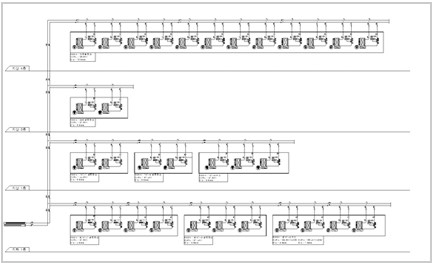

Schematic diagram, refrigeration load calculation, capacity calculation, piping plan, piping cross-section, and heat dissipation drawing

| Freezer and Refrigeration Project Phase-by-Phase Goals

Refrigerant system diagram 1

Refrigerant system diagram 2